Product Range

Dijko Ovens BV is primarily known for their tunnel rack oven systems used in the industrial bakery industry. The tunnel rack oven system is a modular system in which a wide variety of food products can be produced (such as bread, pastry, cakes and cookies). By designing a system that incorporates all of your required process steps regarding proofing, baking, (vacuum)cooling and freezing, we are able to deliver a truly unique system. Because of its modular design, the system is highly flexible, so multiple types of products, each with their own required process steps, can be produced on one line. Par-baked, fully baked, proofed and frozen, bread or pastry, it is all possible in one complete system. We fill the need for a flexible and adaptable baking system, making it possible to produce many different products on one line, keeping costs at a minimum. With the possibility of automating the entire line, we make some of the most advanced systems in the world.

Apart from supplying the industrial bakery industry with revolutionary solutions, Dijko is able to use its knowledge of the industrial bakery industry and incorporate it into other industries, be it food or non-food. We are therefore able to offer specific solutions for drying, conditioning and heat treatment installations. Please do not hesitate to contact us with your inquiry.

Our Machines

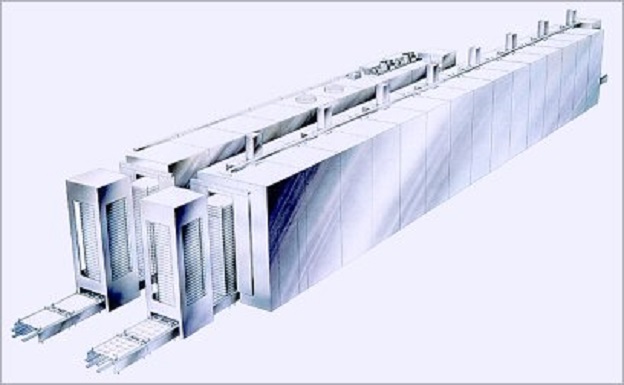

Tunnel Rack Oven System

The Tunnel Rack Oven System is the “bread-and-butter” system for Dijko, that uses racks and trays for transporting products through the system. It is a completely modular system, that comprises of different sections, which are tailored to the customers demands.

Available sections include proofing, baking, (vacuum)cooling and freezing. The Tunnel Rack Oven System can be fully automated by using automatic tray stacking and unstacking, as well as a complete tray transport solution (including for instance tray depanning, tray washing and tray storage).

As a low cost alternative, semi-automation is also an option, in which the racks are manually loaded and unloaded by employees, as well as positioned in front of the system. Movement through the system itself is always automated).

Because of its modular nature, future expansion of the system (to move to a higher level of automation or to increase capacity) is a breeze, and can typically be carried out in a matter of days.

Tunnel Oven System

The Tunnel Oven System with tray stacking is an alternative to the Tunnel Rack Oven System.

The difference is that no racks are used in this system. Stacks of trays run on conveyors through the system. This system is ideally suited when, for instance, products such as steam buns need to be made.

All sections as mentioned in the Tunnel Rack Oven System are also possible in the Tunnel Oven System with tray stacking.

This system can only be offered fully automated.

Specialty Ovens

Apart from the tunnel (rack) oven systems, Dijko Ovens BV has extensive experience in designing and manufacturing specialty ovens and machines for specific product treatment and processing. Some examples are:

- Heat treatment of wood, (outdoor installation with two full wagon carts entering the oven).

- Drying of assorted products (food and non-food), such as pill filler material and rice crackers.

- Preheating components such as steel sprockets for further processing.

We at Dijko look forward to exploring the possibilities for your specific needs.

Address

Dijko Ovens BV

Dr. Hub van Doorneweg 44

5026 RA TILBURG

Contact Us

Phone:+31 (0)13 594 22 11

Fax: +31 (0)13 594 22 12

E-mail: info@dijko.com

Opening hours

Monday - Friday: 08:00 - 16:30

Saturday: closed

Sunday: closed