We fill your needs for a flexible and adaptable bakery system

Dijko, specialized in industrial proofing, ovens, (vacuum)cooling and freezing systems, is well known for its modular bakery systems. We fill the need for a flexible and adaptable bakery system, making it possible to produce many different products on one line, keeping costs at a minimum. With the possibility of automating the entire line, we make some of the most advanced bakery systems in the world.

Modular Bakery Systems

Discover our Dijko Modular Bakery System, allowing you to start your new production line at a moments notice.

Automation

Dijko has extensive experience in upgrading existing, non automated, Dijko systems to a fully automated system, and in supplying completely automated systems from the start.

Specialty Systems

Apart from the bakery industry, Dijko is also involved in supplying systems in other (non-food) fields, where products need to be conditioned to certain specifications. This has resulted in specialized solutions for product conditioning, whether for cooling and heating, drying and moisturizing, or any combination.

Our Bakery Systems

Modular Bakery System

Our Modular Bakery System is unique,. It has been specially designed for use in bakeries and confectioneries where products are baked on trays or in tins.

Specialty Systems

As a complement to our Modular Bakery System, we offer a multitude of custom-built solutions for specific applications.

Applications

Dijko offers solutions to produce all major types of bakery products, such as (tin)breads, pastries, cakes and cookies. Even if your products do not fall in this range, do not hesitate to contact us!

Bread

Using our Modular Bakery System, capacities can range from anywhere between 500 kg/hour to 5.000kg/hour.

Pastry

Our solutions can be used to produce regular pastries, but also long-shelf-life pastries.

Cakes

Our solutions can be used to produce regular (sheet)cakes, cupcakes, muffins and brownies, with capacities reaching as high as 4.000 kg/hour.

Cookies

Using our solutions for cookie production, both semi- and fully automated.

Discover opportunities together, let’s bake success!

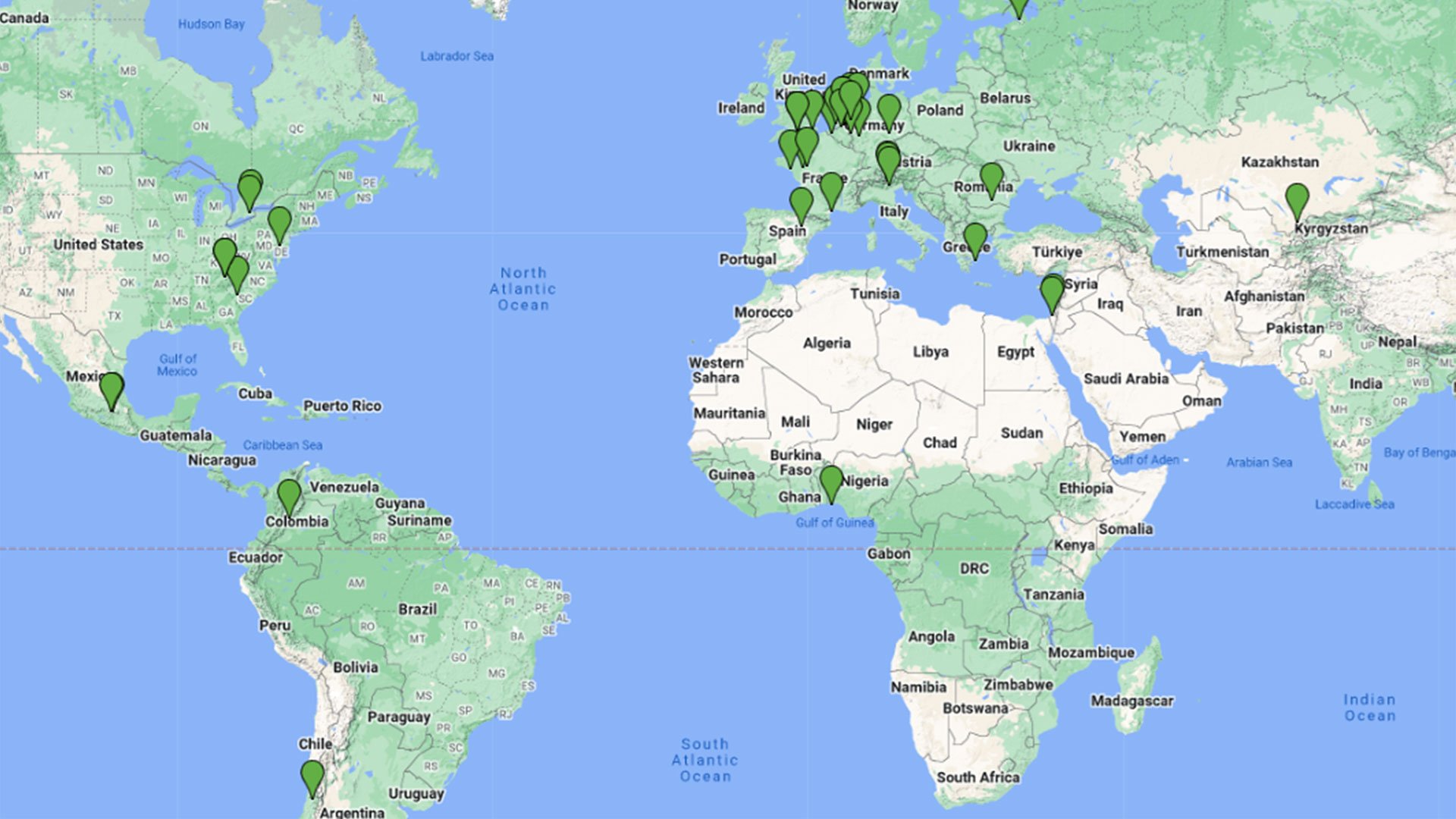

Worldwide representation, combined with our main office in Tilburg, the Netherlands, means we can quickly get in touch to discuss your next project.

Meet us at these events

Dijko will be exhibiting at or visiting the following events.

iba Düsseldorf 2025